![]()

Documentation and enhancements developed by

James R. Holt, Ph.D., PE

Associate Professor Engineering Management

Washington State University

Feel free to use this material when you credit to the source.

THE DICE GAME(s)

Purpose of Dice Games:

While many people understand normal variability (rolling a single die or a pair of dice) in independent environments, few understand the impact of interdependency. By rolling a die and moving tokens through simple structures, the student sees and feels the effects.

The simulation need not be complex. Simple experiments quickly demonstrate basic principles. There are several variations that illustrate different concepts. And, there are recommendations for the instructor who wants to teach robust systems analysis using manual simulation.

Equipment:

Dice: These dice games are played with simple, six sided, fair die available at most grocery and convenience stores.

Tokens: Any available object can be used as a token. Poker Chips, glass beads, kidney beans all work well. Jelly beans, M&Ms, Jolly Ranchers all seem to disappear during play.

Container: While not mandatory, having some paper cups on had helps keep raw material and finished goods in order. Using an opaque cup allows the finished goods to remain hidden until counted.

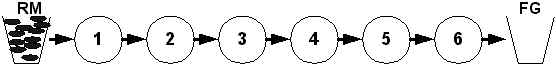

Basic Game (Traditional Push):

The simple dice game is based on the match game Alex played the boy scouts in chapter 13 of The Goal.

In this game, tokens are pushed as fast as the system can produce them (traditional manufacturing system) from raw material to finished goods.

The system includes the cup of raw material tokens (minimum of 40), several individuals acting as workers a row (minimum of 5 people), and the cup for finished goods. Each person (worker) has a fair die.

Discussion: A guided discussion of selected elements of the system will enhance the student's learning. A sample discussion is provided:

Explain the basic sequence of the game. Worker 1 removes tokens (raw materials) from the cup according to the number of dots rolled on the die. The tokens are moved to a point between Worker 1 and Worker 2. Worker 2 rolls the die and processes (moves) tokens from between Worker 1 and Worker 2 to between Worker 2 and Worker 3. Then number processed is the maximum of the number rolled and the number of tokens available (WIP) at that location.

Encourage each worker to examine the die and count the dots to see if it is a fair die. (This is important if you choose to use a weighted die later.) Explain a fair die has 21 dots and six sides for an average of 3.5 dots per side and a standard deviation of 1.8.

Explain you will be playing the game for ten days. Each worker will roll the die once each day.

For most students, it is worthwhile to review a bit of basic statistics. A single die can only roll six values, one each of 1,2,3,4,5,6 (like a uniform distribution). Adding two die together gives one way to roll a 2, two ways to roll a 3, three ways to roll a 4, four ways to roll a 5, five ways to roll a 6, six ways to roll a 7, five ways to roll an 8, four ways to roll a 9, three ways to roll a 10, two ways to roll 11, and one way to roll a 12 (a triangular distribution). The more dies added together the more 'normal' the distribution becomes. With 10 rolls added together, the distribution is indistinguishable from a normal. There is only one way to roll a 10 or 60 but thousands of ways to roll 35. Drawing these curves helps the student understand the central limit theorum.

The expected total for ten rolls would be 10 * 3.5 = 35 with a standard deviation of about 4.5. The maximum possible value is 60 (10*6). The probability of rolling 10 each ones or 10 each sixes is very remote. In fact 70% of the time, the sum of 10 rolls will be between 30 and 40.

Ask the students to record both their roll of the day and the number moved for each day. (If you have enough people, you can assign an inspector for each worker to record the rolls and check the movement of tokens.)

To make the game interesting, let's offer a reward. Have each worker record the rolls he/she makes. Those who roll 30 or more get to keep their jobs. Those who roll 35 to 40 receive 'Superior Ratings'. Allow individuals to guess how many they will roll. Those who roll more than 40, receive 'Outstanding Ratings'.

Begin the play. Play sequentially allowing everyone to observe the rolls as they happen. Worker 1 goes first, then Worker 2, then Worker 3, to the end. The last worker puts the completed tokens in the Finished Goods cup. Remind students to record their roll and their actual production.

The WIP (work in progress) will ebb and flow through the system. Quite often, workers will roll a high number but only have a few tokens to move. Make sure they record the high number and only move the few tokens. While cheating is fun, it lessens the learning for this first time. They can cheat later.

After 10 days, stop the simulation. Keep the WIP in position. Take time to discuss individual efficiency before counting the finished goods.

Discussion: How well did you do? Did each worker achieve their potential (moved as many tokens as the number of dots they rolled)? Who did perform up to their potential and who did not? What should we do with those who with those poor producers?

Did everyone roll over 30? If not, the individual who rolled less is fired. For those rolling 35 to 40, give them acknowledgement for being good workers. For those rolling 41 or more, give them a standing ovation. They are in the top 15% of all producers!

Then, explain the reason we are concerned about workers achieving their potential and each worker producing more than 30 is because 30 is the break-even point for the company. If you don't make at least 30, you will not make a profit. And the company is in serious financial trouble. One more week of no profit and the plant will close.

Now, count the finished goods in the cup (WIP on the table doesn't count). The average will be close to 25 with a range from 16-28.

"Oh, no! What happened! We had several people earn recognition, even rewards but the rest of you let the company down! Now, we must close the plant! How could this be? There is less than 1% chance of you being this low (average of 35 less two standard deviations puts 25 at the 1% mark). Perhaps if we played the same game again, we could save the company."

Before playing the game again (or disturbing the game) count the WIP in the system (don't count the raw material) and note it.

A repeat play of the same game will produce similar results. If you had an anomaly (someone who rolled 25 by themselves or somehow did produce 30) run the simulation again.

Some students will claim the reason they didn't reach the expected value (35) was because they started out without any inventory. You can easily clear up that assumption by playing ten more days STARTING WITH THE SYSTEM AS YOU ENDED IT after the first ten days. The system will still fall short (below average every time).

So, what was it? The high variation of the die? No, not really. The high variation of the die just allows us to see the action of the system quickly. The real issue is the interdependency! Most of the time, when one worker had a high roll, there was not enough WIP to take advantage of it. Individual efficiency does not mean high system efficiency.

Advanced Games:

Variation on the Traditional (Push) game: Pre-load the line with WIP. Try placing three tokens between each worker before the game starts. Play the game but have individual raise their hand if they roll a number higher than the WIP available. Stop the game when someone raises their hand (probably by day 6). Replay starting with 6 tokens between each worker. Play again. You might make it 20 days. Notice the increased finished goods inventory is really only due to the reduction in WIP as the system approaches steady state. Even starting with 6 tokens between each worker, by day 20, the system appears very close to the same as the system at the end of the first 10 days without any pre-loaded WIP.

Kanban or Just-In-Time (Pull) game: In this game, instead of workers rolling in sequence from raw material to finished goods (from Worker 1 to the end), you roll starting with the last worker and end the day with Worker 1 rolling. Pre-load the line with WIP. You must have enough to cover the maximum demand. So, put 6 tokens between each worker (total of 24 or 30 depending on how many workers you have).

Play the game. The last worker rolls to determine the 'demand' on the system. On day 1, the last worker moves the tokens into the finished goods cup according to the roll of the dice. The next to last worker rolls and tries to replenish the WIP before the last worker to its Kanban level of 6. Sometimes the next to the last worker will be short and will have to make up the shortage on future days. Sometimes the next to the last worker will roll a high number and could exceed the Kanban level. Don't allow the Kanban level (WIP between two workers) to go above 6 tokens.

Continue each day by bumping the localized demand back to the raw material, each worker trying to just replenish the Kanban level following them. The last worker may have rolled a 6, but if Worker 2 only moves 1 token, then Worker 1 only replaces 1 token.

You will notice the system runs find for 3 or 4 days, then it breaks down. In a short game of 10 days, the Kanban system will produce more than the first traditional push game. This is because so much WIP was positioned near the end of the line. But, in a 20 day game, the Kanban system will rarely produce as much as the traditional push.

Theory of Constriants Approach-DBR (Pull control up front with push everywhere else: With the TOC approach, you need to create a constraint. In reality, we do this by speeding up everyone but the constraint. To keep things in perspective and make these dice games comparable, we create the constraint by reducing capacity of one of the workers. An easy way to do that is to use a loaded die. (Use White-Out to 'erase' two of the dots from side 6 of and one dot from side 5 of a fair die to produce a weighted die that averages 3.0 per side. Or create a five sided die by simply ignoring the 6 side. If you roll a 6, ignore it and roll again. A five sided die averages 3.0 per side). Give the constrained die to a middle worker, say Worker 3). To create the buffer, pre-load the line with 10 tokens right before the constraint worker. This large pile of 10 looks huge, but it is much less than the 24 or 30 used in previous pre-loads.

Begin by Worker 1 rolling the die on day one. No matter what Worker 1 rolls on day 1, no tokens will be moved. Worker 1 only moves in tokens if the amount of WIP between the raw materials and the constraint (WIP between Worker 1 and Worker 2 and WIP between Worker 2 and Worker 3) is less than the buffer amount of 10. So, on day 1, while Worker 1 and Worker 2 will both roll, they will not move any tokens. Worker 3 (the constrained worker) will roll on day 1 and move tokens. Those workers down stream will work as usual. On day 2, Worker 1 will try to replenish the buffer. This means to return the level to 10. On day 2, Worker 1 will move a maximum of what Worker 3 rolled on day 1. If Worker 1 rolls a smaller number, the buffer will be slightly depleted. But, Worker 1 has excess capacity and should be able to catch up. Worker 2 does its best to move available tokens to the constrained Worker 3. Play continues for ten days.

With DBR, the system should out produce all the other systems. EVEN WITH THE CONSTRAINED DIE! The average will be around 30 for the ten days with a range of 27 to 33. If the class is skeptical, play the game over or extend it. You will notice the inventory is very predictable and the production level is calm. It doesn't matter how long you play, the average production stays at 3 per day.

Discuss what DBR did to improve the system? Was it reduced variability? No. Was it increased inventory? No. Was it increased capacity? No. Then what was it? It was reduced dependency. Having a constraint de-coupled the interdependency of the balanced line. The buffer protected the available capacity. The rope restricted inventory growth.

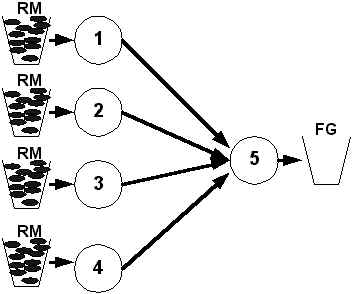

Assembly Model: Assembly operations provide a dramatic illustration of dependency. Consider the simple assembly of four workers feeding a single assembly worker. Each raw material is a different color token. The assembly worker must have one of each color to product the product.

Each day, Worker 1, Worker 2, Worker 3 and Worker 4 move produces towards Worker 5. Worker 5 will try to produce as much as possible but is limited by the dice roll and the availablity of tokens of each color.

Complex Assembly/Routing Model: Once the students understand the effects of dependency, you can test their skill on a more complex model. There are an infinite variety of structures. Here is a sample using 9 workers. Worker 5 combines work from Workers 1 and 2 into an assembly that becomes a single common part (two things become 1) which can be used by Worker 7 or Worker 8. The same thing happens with Worker 6. Worker 8 also forms an assembly of two parts from Worker 5 and Worker 6 to provide on FG 2. To produce FG 1, you need only RM 1 and RM 2. To produce FG 2, you need one of all four raw materials combined in two sets. FG 3 requires RM 3 and RM4. Try to produce equal amounts of all three finished goods. To set up the system, give each worker one die and then take 6 more dice and give them to the workers at random (1 extra per person). Three people will have a single die. Run the system for ten days in the normal fashion. Offer the students a chance to 'upgrade' capability by 'buying' extra dice for a significant price. Allow them to experiment on how many dice to buy and where they could put the dice to produce the most.

Advanced Equipment:

Dice Modifications: The avid simulator may choose to change the die values (use white out to 'erase' some of the dots on the die) so die of different values are created (blotting out two dots on the 6 side, and 1 on the 5 side gives a nice die averaging 3.0). Or, you could ignore a face to change averages (ignoring rolls of 6 and re-rolling the dice gives an average of 3.0) Additionally, dice with 4, 8, 12, 16, 20 sides are available at specialty game stores. In a pinch, three coins (penny, nickel, quarter) can be used to produce an eight sided fair die.

|

Value |

Penny |

Nickel |

Quarter |

|

1 |

Head |

Head |

Head |

|

2 |

Head |

Head |

Tail |

|

3 |

Head |

Tail |

Head |

|

4 |

Head |

Tail |

Tail |

|

5 |

Tail |

Head |

Head |

|

6 |

Tail |

Head |

Tail |

|

7 |

Tail |

Tail |

Head |

|

8 |

Tail |

Tail |

Tail |

Ó

Copyright Washington State University 2000